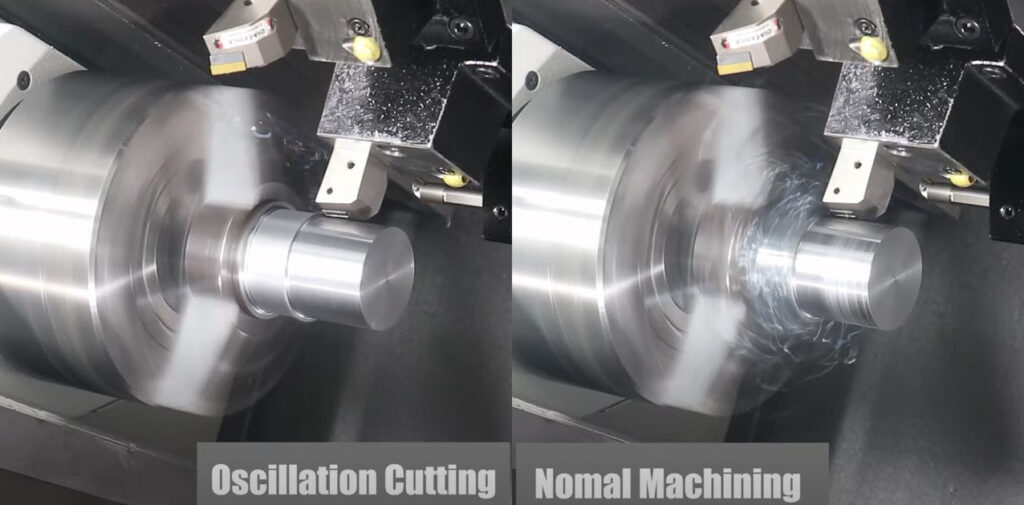

Turning is defined as the action of turning a workpiece set on a spindle and cutting the surface by a tool as if peeling an apple. As you may know, while a machine is turning, it brings many of long chips continually and the chips get entangled to the workpiece or tools before long. This could be a major trigger to disrupt the automation, but if you assimilate Nakamura-Tome’s oscillation cutting, you can solve this problem.

The oscillation cutting is a machining method that vibrates the tool to break up chips into small pieces, prevents the long chips from getting tangled up, and achieves greater discharging efficiency.

Once a machine is equipped with a NC option of the servo learning oscillation function and upgraded software, the program can be easily executed by G code. This is one of the appealing points of our oscillation cutting function.

Let’s learn about the mechanism of oscillation cutting, the G code command, and FAQ regarding the function from the following videos.

1.Newly equipped oscillation cutting function

Since this video was released in February 2021, the number of compatible machines has been increased at the present time of writing, but it is still helpful to know what the oscillation cutting is and to watch a demonstration.

2.Oscillation cutting with a large machine

After we released the first seven line-ups in February 2021, we went public this video in August 2021. In this video, you can see some big machines have been added to the line-ups, and learn questions and answers related to the oscillation cutting as well. Please check out the comparisons between the oscillation cutting and normal machining appearing around 5:44 in the video.

3.Summary

This oscillation cutting function is able to be equipped with a machine already installed in your plant, if it meets certain conditions. Why don’t we take an account of this function as one of the options to solve the swarf problems?

Please feel free to contact us from the Oscillation Cutting corner, or contact our overseas presence and distributers.