-

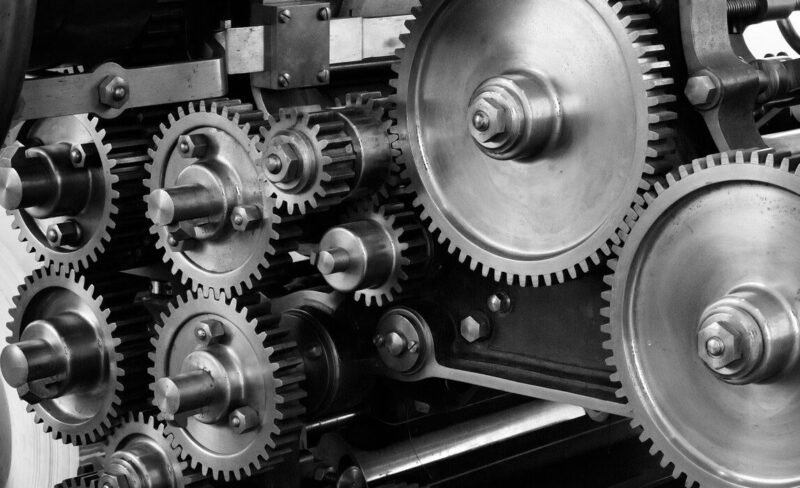

Types of Gears Explained: What Do Their Shapes Mean?

A gear is a circular or cylindrical component with teeth along its outer edge. Gears work by meshing together to transmit, modify, or adjust power from motors or other driving forces.

-

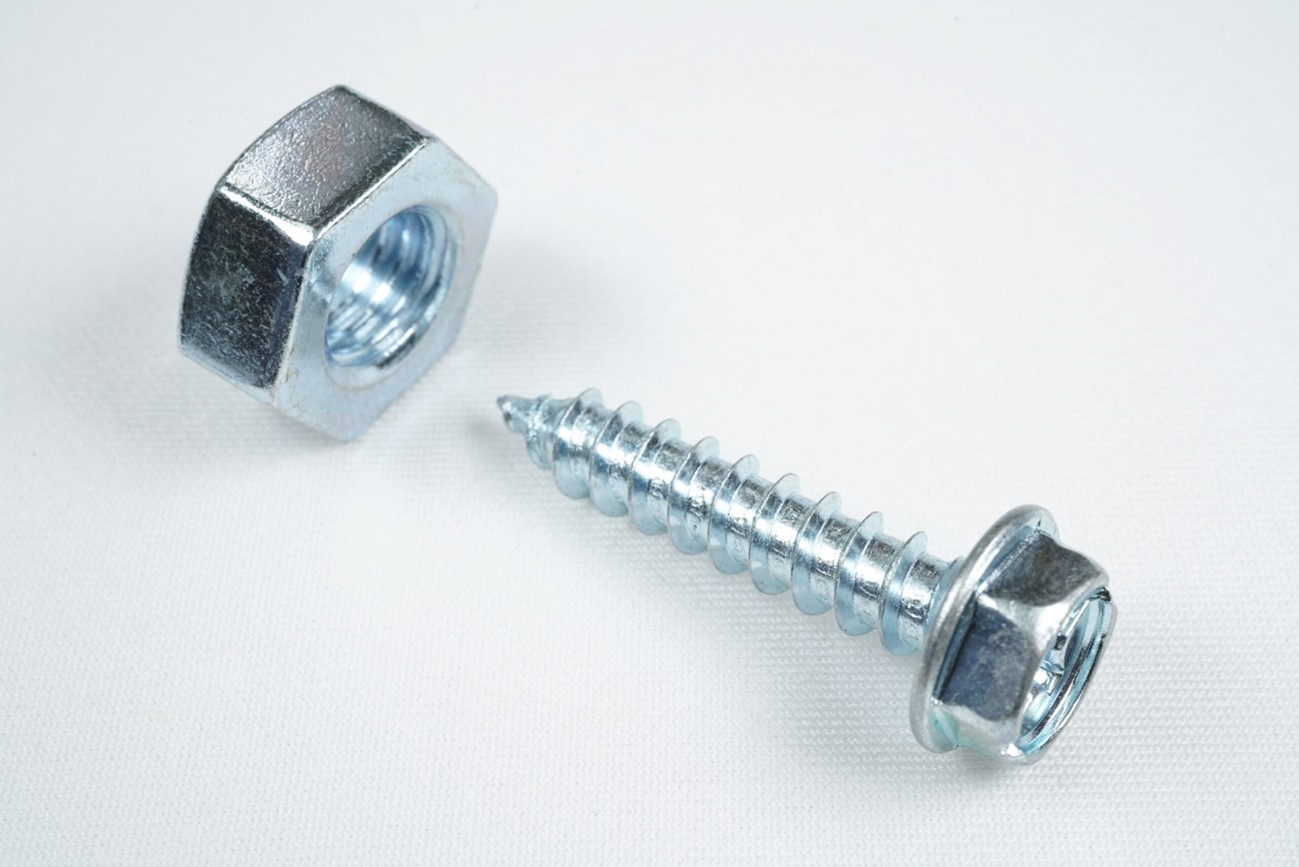

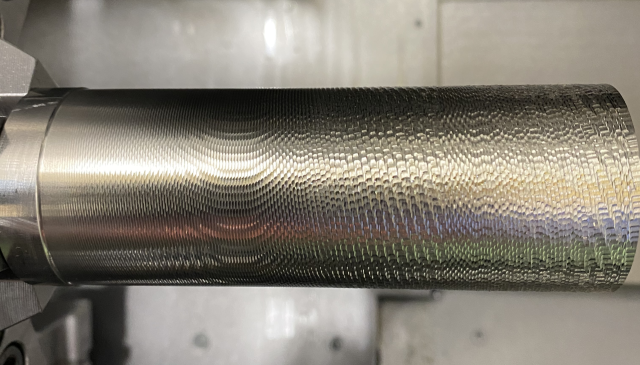

Guide to Thread Cutting with Processing Programs

The threads you see every day without much thought come in various types depending on where they are used, their purpose, and the materials they are made from. This time, we’ll explain about metal threads that are commonly machined through cutting processes

-

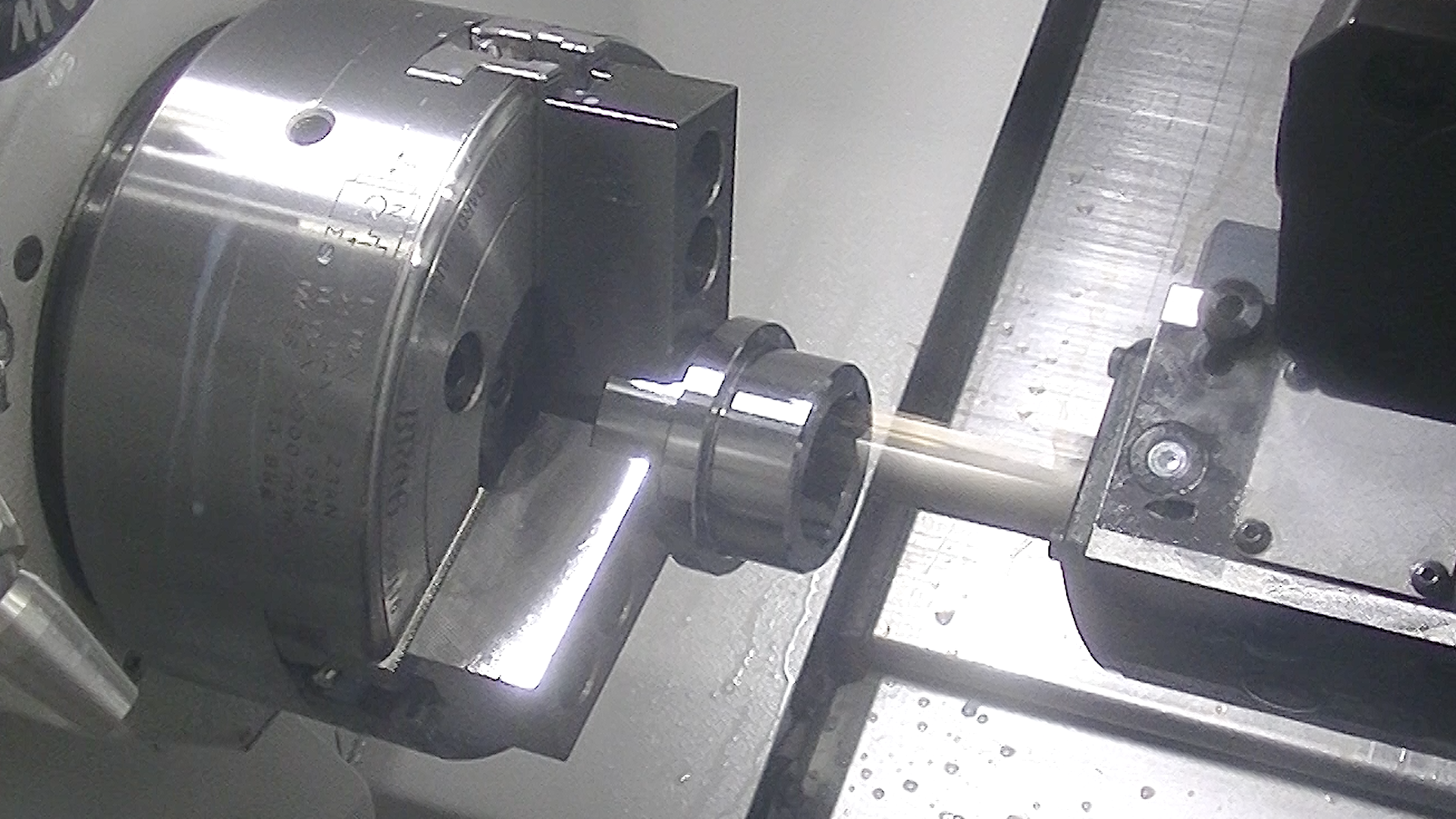

【CNC Lathe】Know-How for Reducing Cycle Time!

The cycle time per product is determined by the created NC program, but by reviewing and optimizing this program, the cycle time can be shortened. This article explains the key points of cycle time reduction that manufacturing engineers implement.

-

Machining Internal Keyway with Slotting Tool

Several methods exist for performing internal keyway milling, including using a slotting machine, a broaching machine, or an electrical discharge machine. However, a multitasking machine can also perform this operation. In this article, we will introduce keyway milling using a slotting tool with multitasking machines or lathes.

-

Cutting Chips in Machining: A Mine of Information!

When machining metals with machines like lathes or milling machines, various shapes of cutting chips (helical, ribbon, or broken) are generated. These chips reveal a lot through their color, shape, length, etc.

-

What Are Cutting Conditions? How Should They Be Determined?

To perform machining, a machine tool needs to have specified numerical values for cutting speed, rotation speed, feed rate, and depth of cut, which are referred to as cutting conditions (or machining conditions).

-

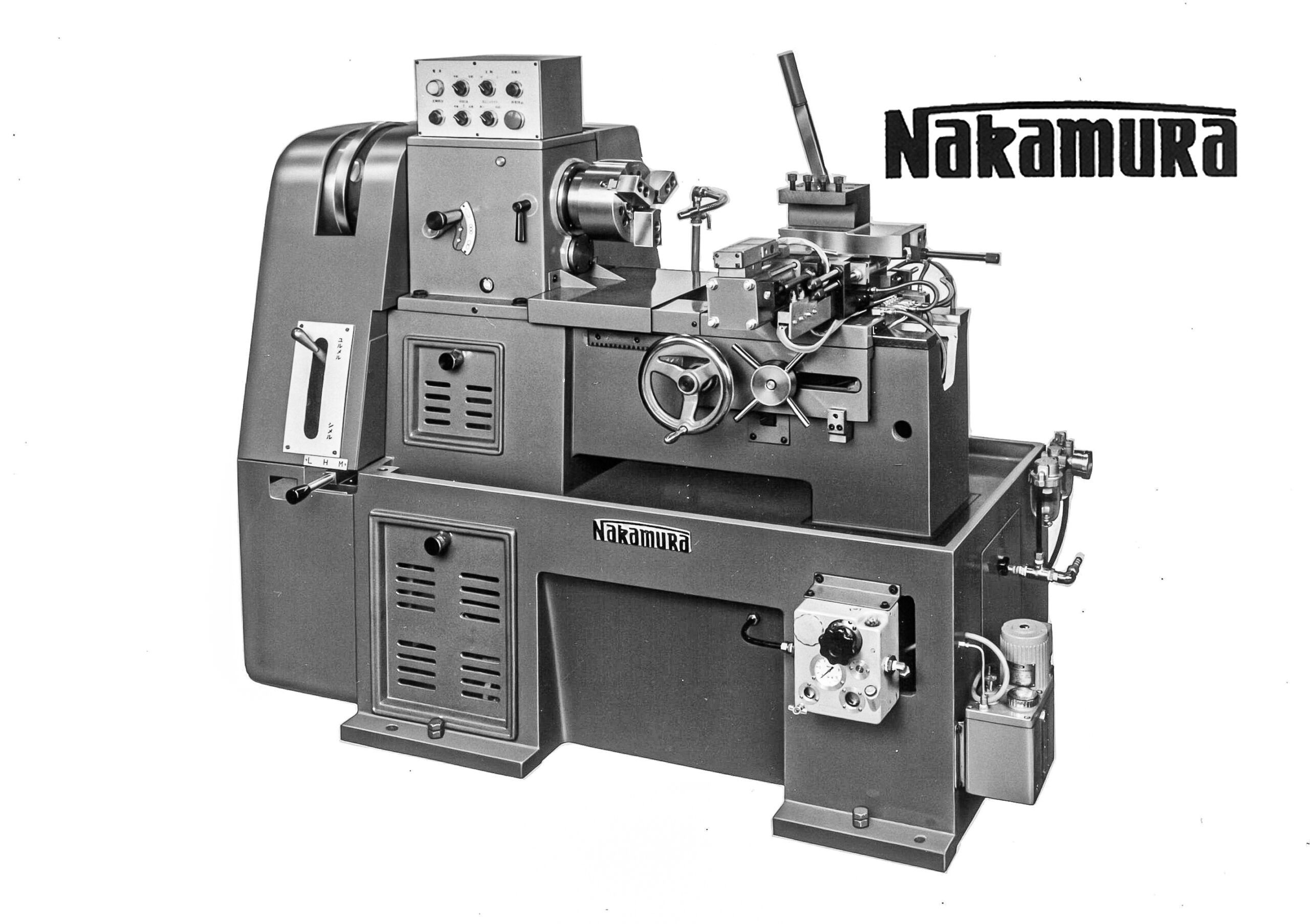

How Big Are the Nakamura-Tome’s Machines?

The size of machine tools varies depending on the types, the methods of machining, and the size of workpieces. Let’s take a look at how big the Nakamura’s machines are.

-

Six Key Points to Minimize Chatter in Machining!

If you’ve been involved in machining, you’ve probably experienced “chatter” on the machined surface at least once. Chatter tends to occur more easily, especially in I.D (internal diameter) turning, where tools are extended longer. This time, we will introduce six points to review when chatter occurs during machining.

-

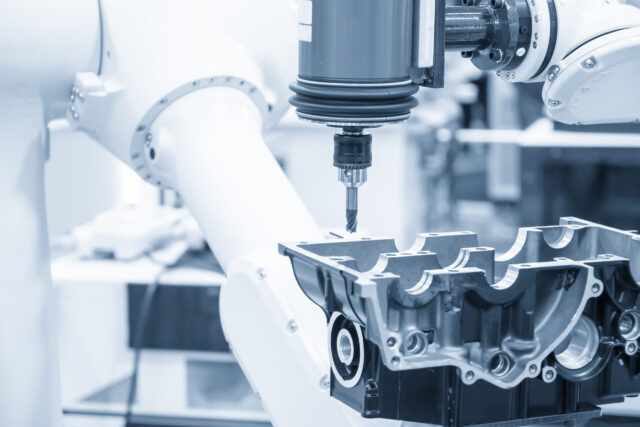

Benefits of Machine Tool Automation! How Do You Introduce Unmanned Machines into Your Factory?

Many workplaces use manually operated machine tools, such as general-purpose lathes or milling machines. However, these tools are not suitable for mass production because of difficulties in achieving high precision and the need for skilled operators. Therefore, in recent years, the development of automation technology for various operations using machine tools has progressed.

-

What Is a Lathe? Explain the Machine Configuration from the Processing Target!

What is a lathe? Explain the machine configuration from the processing target!

Latest Articles