Most of the parts produced by machining are made using several types of machine tools.

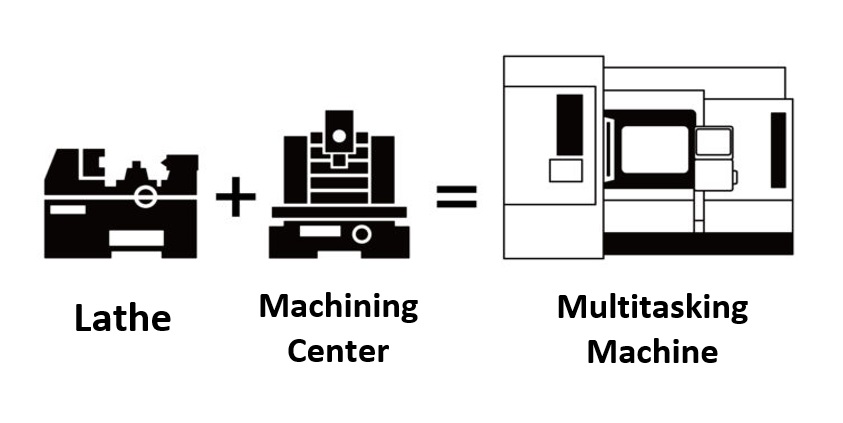

A multitasking machine is a machine designed to perform several types of machining with a single machine, instead of using several types of machine tools. Multitasking machines are the result of continuous efforts to consolidate processes in the long history of machine tools.

1. What is a multitasking machine?

A multitasking machine is a machine equipped with an automatic tool changing function (including turret type). A multitasking machine is a numerically controlled machine tool equipped with an automatic tool change function (including turret type) and capable of performing multiple types of machining such as milling, turning, and grinding without changing the workpiece setup.

The most significant feature of the machine is that a single multitasking machine can complete multiple machining processes.

In most cases, at least two machine tools, such as a lathe and a machining center, are required to finish a single part from material to finished product, but a multitasking machine can complete all these processes with a single machine.

2. Difference from a lathe and CNC lathe

Lathe (Manual lathe)

A lathe is a machine that rotates the material to be processed and shaves it into a cylindrical shape by applying a blade. Among them, a general-purpose lathe must be operated manually by a craftsman with feeling and experience.

NC Lath

A NC lathe is a general-purpose lathe equipped with an NC device that operates automatically by programming.

Multi-tasking machine

A NC lathe that is equipped with a milling function on a NC lathe and can perform various types of processing is called a multitasking machine. The greatest feature of a multitasking machine is that it can be used in a wide range of applications.

3. key points of multi-tasking machine

Consolidation of processes and reduction of labor costs

If a multitasking machine is not used, it is necessary to use several machines to produce a finished product from a material, and each time it is necessary for a worker to install, remove, and transport the material.

With a multitasking machine, all of these tasks are performed by a single machine, eliminating the need for workers to attach and detach materials or move materials between processes. Once materials are set, they are ready to be finished, reducing the burden on workers.

Space saving

Since there is no need to have several machine tools for different processes, the number of machines can be reduced and the factory space can be effectively utilized. The production capacity of the entire factory can be increased.

High quality

In terms of machining accuracy, it is said that accuracy deteriorates as the number of mounting and dismounting operations increases, and positioning during mounting is important. In the past, it was necessary to install and remove materials for each process, which could lead to slight deviations. However, by machining with a single multitasking machine, it is possible to eliminate the installation and removal processes that can cause a decrease in machining accuracy, and maintain uniform accuracy of the finished product.

4. Typical machining workpieces

The following are some of the parts that are produced by multitasking machines.

All of these parts can be completed with a single multitasking machine.

Drive shaft

This is a drive shaft for automobiles.

Conventional machining processes are completed by lathe turning (one or two processes) + machining center + hobbing (two processes).

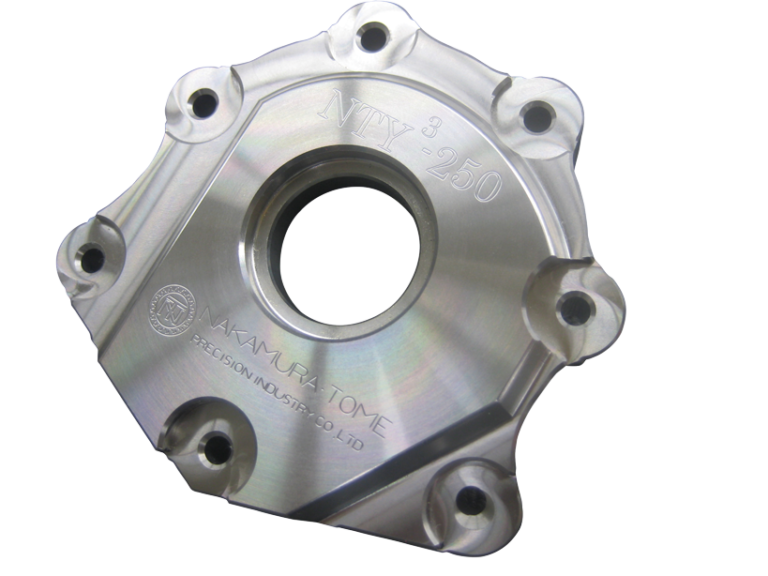

Pump cover

This is the cover of an oil pump.

Conventional machining process is completed by turning (1 or 2 processes) + machining center (1 or 2 processes).

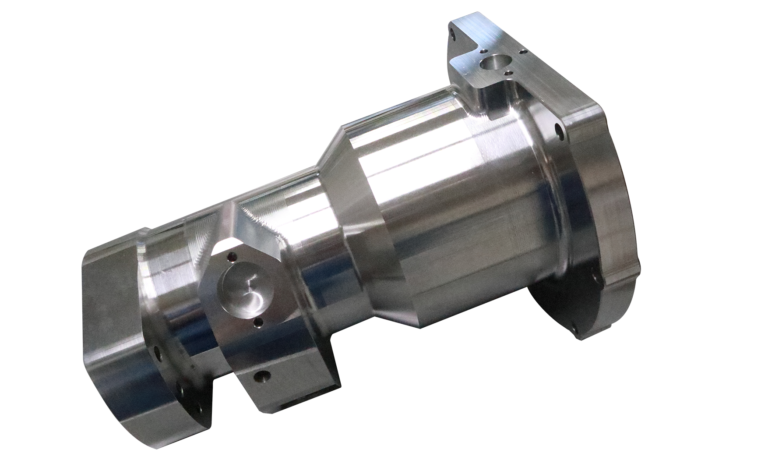

Housing

This is a part used in aircraft.

Conventional machining process is completed by turning (1 process, 2 processes) + 5-axis machining center process.

5. summary

The ability to complete all machining operations with a single multitasking machine is a major attraction. The use of a multitasking machine has great advantages such as increased work efficiency, effective use of factory space, and improved productivity.

If you have NC lathes or machining centers and want to reduce labor costs by consolidating processes, have no space for additional machines in your factory, or want to improve the accuracy of your products, why not introduce a multitasking machine to solve your problems?

Please contact our overseas presence or distributers in your area.