Cutting oil and coolant oil are used in machining. What is the advantage in using a cutting oil? Is it so important? Let’s take a look at the reasons why the cutting oil are important, how to choose one, and what type is recommended for a numerically controlled lathe.

1.The four vital roles of a cutting oil

Do you know why we have to use cutting oil? We need to understand its roles before learning how to select one from several types. A cutting oil actually has four roles when it’s used in machining.

Lubrication

It goes through into the interface between a cutting tool and a workpiece to reduce friction. There are several benefits as follows to reducing the friction:

・Life extending effect due to less abrasion

・Smooth finishing of a machining surface

・Suppression of a rise in temperature

Cooling

When machining is operated on a numerically controlled lathe, the temperature of a contact area of a tool and a machining surface increases up to 600 degrees Celsius because of the friction. Metal changes shapes and the machining accuracy goes down, but if we use a cutting oil, we are able to prevent the heat escalation.

Moreover, if we keep the contact area in a low temperature, we can reprogram its machining conditions to finish a work earlier. In other words, cooling is considered a great way to reduce cycle time.

Cutting chip removal

If we keep machining while chips are piled up, it would be the cause of defective products. Applying a cutting oil makes chips ease to be removed while machining. Moreover, a cutting oil plays a role not only to remove chips, but also to prevents fine swarf generated from lifting into the air in a working chamber.

Prevention of welding

A part of a workpiece or chips melts and melds onto a tool while machining. This process builds a deformed tool so called “a built-up edge (BUE)”, and affects to the debasement of machining accuracy. A cutting oil gets through into the interface between a workpiece and a tool to prevent from generating BUE. This is also considered to be a benefit of cooling in a way, because cooling can prevent work materials from welding.

2.Types and choices

Cutting oils are mainly divided into two types: water-soluble cutting oil and oil-based cutting oil, and they are separated into more small groups.

Let us get straight to the point.

A numerically controlled lathe moves very fast and easily gets exposed to the heat escalation. Therefore, in order to prioritize cooling of a machine, water-soluble cutting oils are often selected.

Oil-based cutting oils are mainly used for hard-to-cut materials to prolong the life of tools. For your further interest, those who work on copper alloys machining tend to choose dry machining without using a cutting oil to avoid from adhering oil to a workpiece or chips.

・Water-soluble cutting oil

This type is often called “coolant” on the field and mainly used for cooling. It is diluted with water and has a low risk of ignition. Therefore, water-soluble cutting oils are relatively comfortable to use for machining 24/7 without operators. However, since the water-soluble type has a tendency to deteriorate easily, careful management would be required.

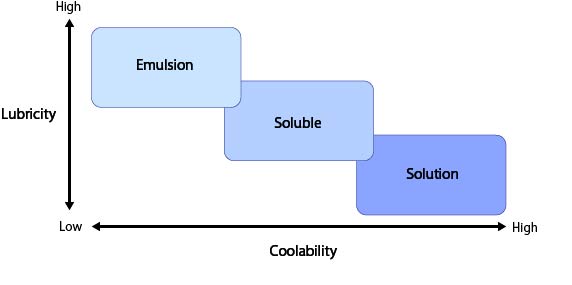

They are divided into three groups by Japanese Industrial Standard (JIS).

| A1 | Milky white (Emulsion) |

| A2 | Translucence or transparence (Soluble) |

| A3 | Transparence (Solution) |

We recommend customers to use Type A1 for use with Nakamura-Tome’s machines.

Please note some of cutting oils may affect negatively to our machines, for instance, paint peeling, cracks in resin products, the expansion of rubber products, the corrosion of copper and aluminum materials. Do not use a synth-tech or chlorine-containing cutting oil as it may cause product failure.

*This caution is only adopted to Nakamura-Tome’s products. Please check separately for products from other manufactures.

・Oil-based cutting oil

This type is aimed at lubrication and welding prevention mainly, introduced in machining that is required the high accuracy of work in the most of cases. On the other hand, it should be handled with careful management because it could cause a fire due to ignition by heat. Therefore, if you use an oil-based cutting oil, you would be required to add the following devices on a lathe depending on a situation.

・Automatic fire-extinguisher system

・A mist collector with an automatic fire extinguishing device interlocking a fire damper

・An automatic liquid temperature regulator

・An air blow device or a coolant blow device

We recommend customers to add an automatic fire-extinguisher device and a fire damper in use of an oil-based cutting oil with Nakamura-Tome’s machines.

*This caution is only adopted to Nakamura-Tome’s products. Please check separately for products from other manufactures.

3.Methods in the control of quality and points to be checked

Cutting oils deteriorate soon affected by the interfusion of chips and foreign materials. Especially, we need to pay attention to water-soluble cutting oils because this type gets colonized by bacteria after diluted with water, and becomes the cause of the decomposition and deterioration of the cutting oils. Let us show you some methods in the quality control of cutting oils, and essential points to be checked.

Appearance

Daily observation on the appearance is needed. If you find floated oil, please remove it.

Smell

The more bacteria increase, the more awful smell arises. Using those contaminated cutting oils would be the cause of corrosion. Those are often seen with water-soluble cutting oils diluted with water.

Concentration and pH(alkalescent)

If concentration and pH are not adequate, it would cause corrosion or decomposition that gives damages on wipers and packings in a machine, and could finally result in a decline in function.

Cleaning of a coolant tank equipped with a machine

It is important to pour a cutting oil after cleaning up a tank. Once a new cutting oil was mixed with the one used in a former machining, the concentration would be changed and lost the component balance of the cutting oil. Moreover, if chips or foreign materials are left in the coolant tank, metallic composition would be melted and mixed into the cutting oil.

4.Be careful with fire in use of oil-based cutting oils!

As we already know, we need to pay attention to using an oil-based cutting oil because it is at risk for fire. Here are some precautions mentioned in our maintenance manual provided with a machine.

Heat generation caused by abnormalities

It would catch fire due to abnormalities caused by the damage of tools, friction, or heavy-duty operations. In order to avoid these conditions, equipping detective devices to sense abnormalities is preferrable.

Unsuccessful approach to a machining point

If a cutting oil fails to touch a machining point, it could not cool down the contact area and may result in catching fire. Please try to adjust the outlet location of the cutting oil to gain a sufficient reach to the point.

Setting of cutting conditions

You might think of programming strict cutting conditions to increase machining efficiency, but this brings the increase of machining resistance that heats chips tremendously, and then the heated chips could become an ignition agent to catch fire. Please avoid from setting too strict conditions and leave some room for it.

・Control in the quantity of a cutting oil

When the quantity of a cutting oil is shortening, outlet pressure also gets lowered. That means a machine is not able to preserve sufficient performance to make the cutting oil reach a machining point. This might result in catching fire. Observing the oil’s quantity habitually is necessary, but we also recommend you to equip with a liquid level detector.

5.Summary

A cutting oil is regarded to be an essential machining partner in these days. However, if we select a wrong type for a wrong machine, it negatively affects to the performance of a machine, that comes to a decrease in machining accuracy and accelerates the aging of tools.

Important things are that we need not only to understand the features and machining conditions of your own machines but also to understand the features of cutting oils for smooth works. Moreover, maintenance after purchase is indispensable.

We, Nakamura-Tome, are delighted to support customers to select a machine and propose processing setups to meet the needs of the customers. Please feel free to contact our overseas presence or distributers in your area.