Automotive

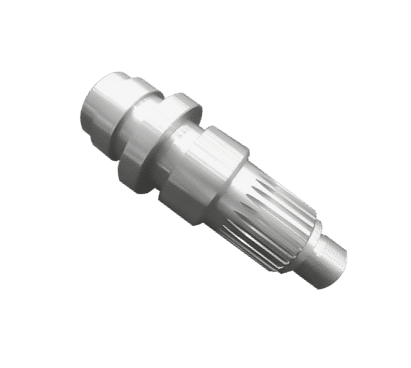

EV Motor Shaft

- φ50 Bar Material SUS303

Drive Shaft

- φ65×175L SUS303

Gear Cam Shaft

- φ80×110L SCM435

Output Shaft

- φ65×450L Quench-hardened steel(HRC62)

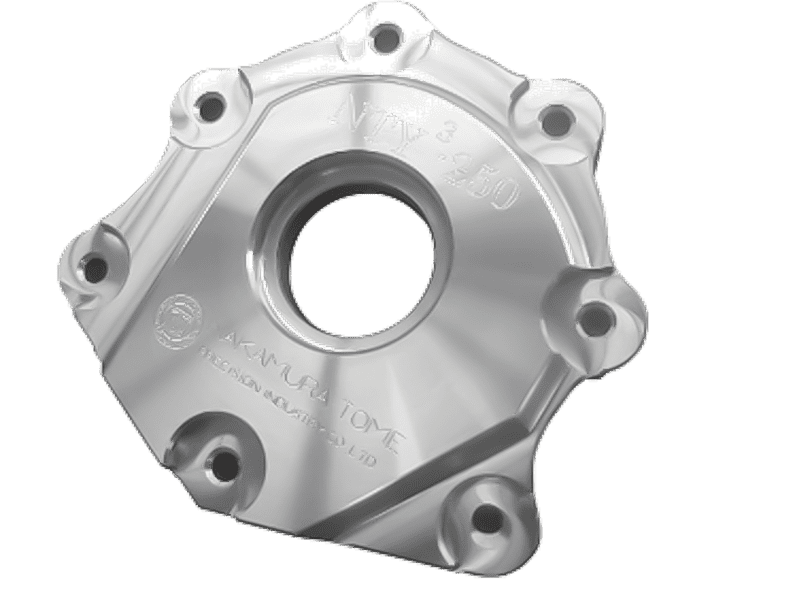

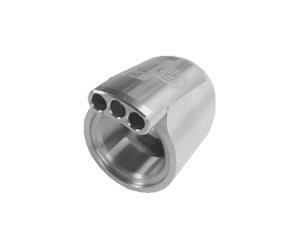

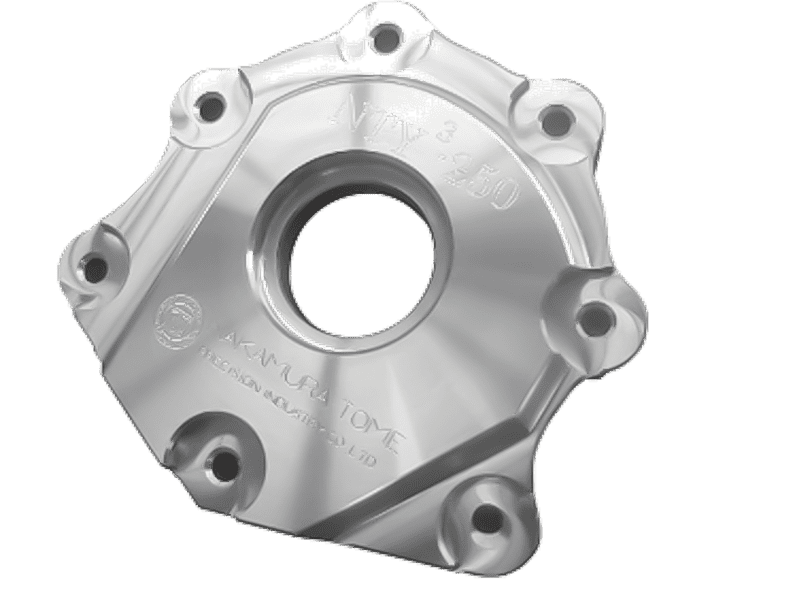

Pump Cover

- φ140×50L SUS303

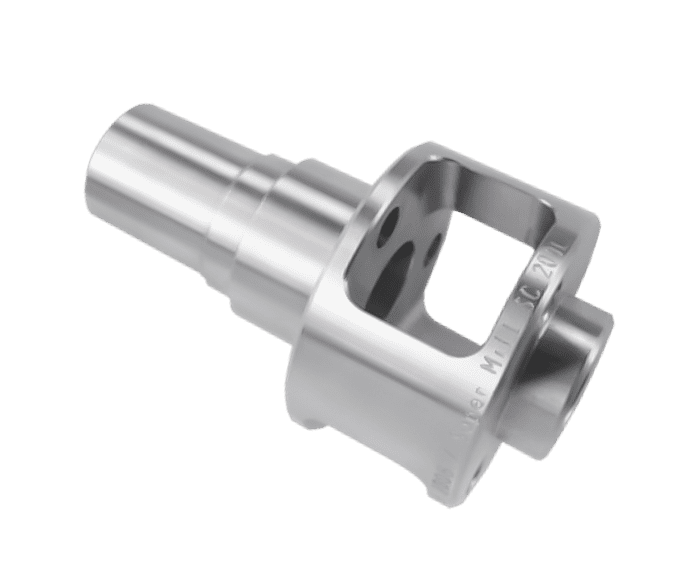

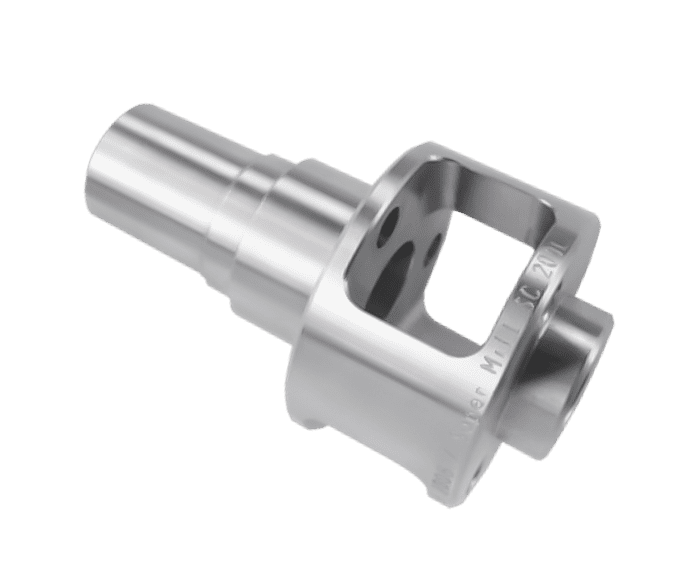

Carrier

- φ65×80L SUS303

Cam Shaft

- φ60 Bar Material SUS303

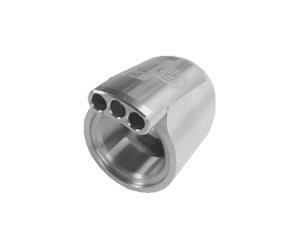

Plug in coupler

- φ50 Bar Material SUS303

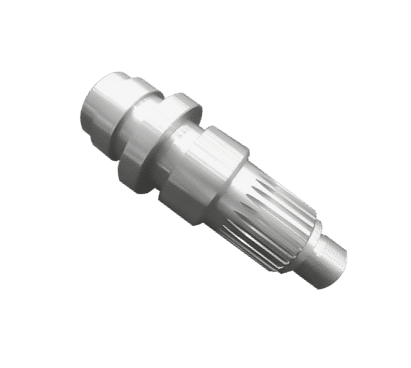

Input Shaft

- Φ70×150L SCM420

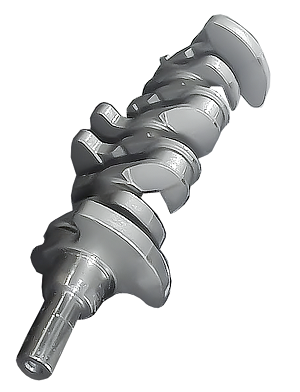

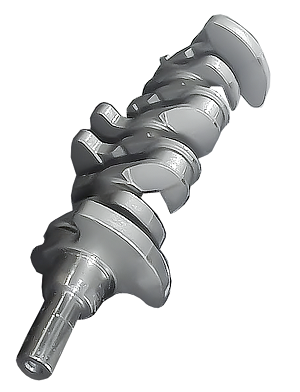

Crank Shaft

| Diameter | φ50 |

| Material | Bar Material SUS303 |

Point By supporting the L side with the lower turret and machining with the upper left turret, while machining the R side with the upper right turret, shaft work can be processed efficiently. Additionally, gear machining through milling is also possible.

Click to play video

| Diameter | φ65×175L |

| Material | SUS303 |

Point The stabilization of coaxiality by center support allows for multiple gear processing on a single machine, simplifying gear phase alignment significantly.

Click to play video

| Diameter | φ80×110L |

| Material | SCM435 |

Point High-efficiency processing has been achieved through cam shape machining with polar coordinate interpolation, simultaneous milling and turning on both upper and lower turrets. Complex shapes involving multiple workpieces can also be machined with a single machine.

Click to play video

| Diameter | φ65×450L |

| Material | Quench-hardened steel(HRC62) |

Point High-speed machining of high-hardness materials is possible through the combination of center support and hard skiving.

| Diameter | φ140×50L |

| Material | SUS303 |

Point Due to the numerous machining processes, a machine with three turrets and a large diameter was selected. It is possible to machine the reverse R side while performing simultaneous upper and lower machining on the L side.

Click to play video

| Diameter | φ50 |

| Material | Bar Material SUS303 |

Point Achieve high-precision milling using tool axis and turret for complex processing of irregular workpieces with high added value, small diameter deep-hole drilling, and machining from bar material

Click to play video

| Diameter | Φ70×150L |

| Material | SCM420 |

Point Two different types of gears can be machined on a single machine, and gear phase alignment is stabilized with one-chucking machining. Additionally, gear cutting with M module 2.5 can be performed under the same conditions as a hobbing machine and in a single pass.

Click to play video

| Diameter | - |

| Material | - |

Point

The fully automated system enables high-efficiency, high-precision crankshaft processing on a multitasking machine.

On the WT-300, counterweight end faces, journal sections, and shaft end-face processing—including hole drilling—are performed. End-face processing is stabilized using a steady rest attached to the lower turret. Once completed, the crankshaft is unloaded by a robot and automatically transported to the Super NTJ.

On the Super NTJ, the B-axis swiveling turret is utilized for deep hole drilling of oil holes and keyway milling, all achieved in a single chucking. Furthermore, phase detection by the NT Work Navigator and smooth transport using the temporary stand on the lower turret enable high-quality processing in a short time.

Click to play video

Click to play video