Aerospace

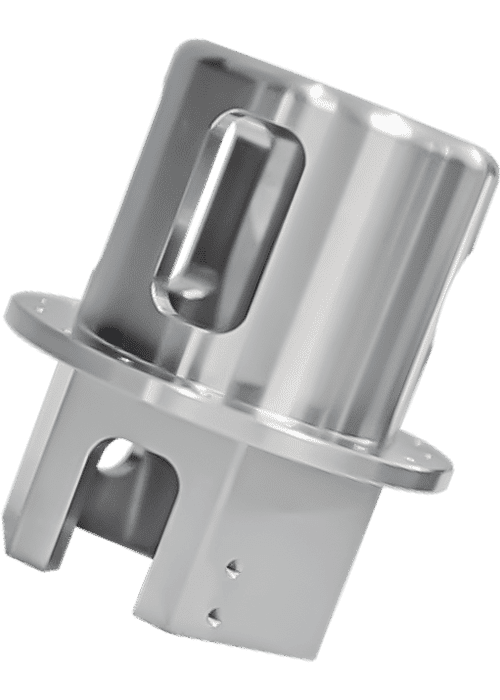

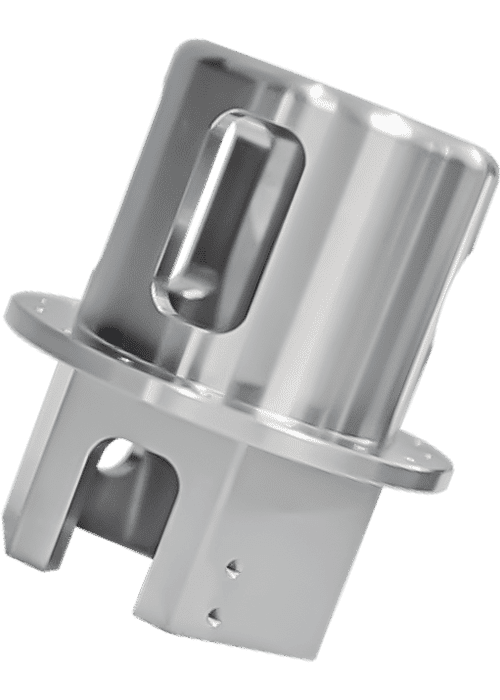

Joint

- φ100×110L SUS303

Aircraft Joint

- φ70×100L SUS303

Connector

- φ50 Bar Material SUS303

Connector

- φ50 Bar Material SUS303

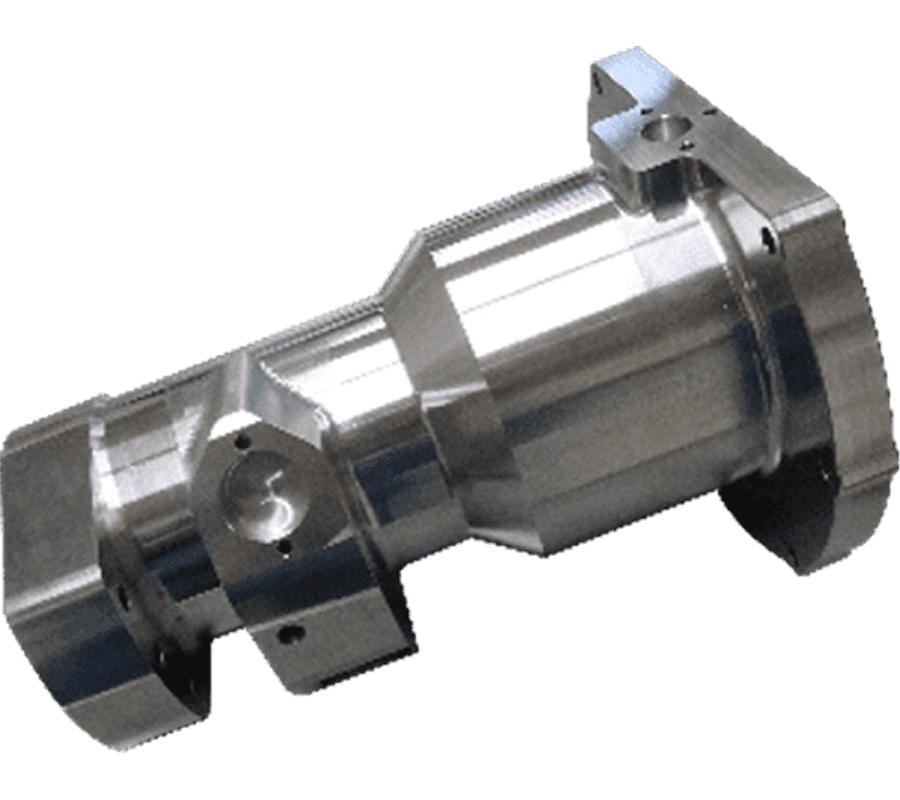

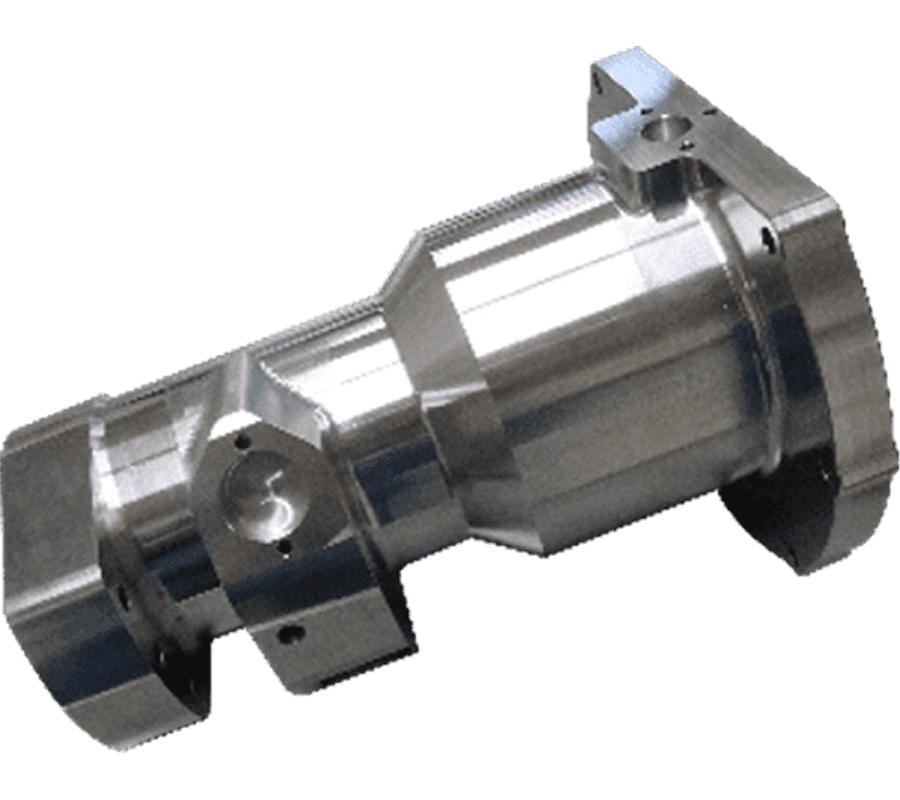

Housing

- φ200×255 Aluminium A7075

Joint

- φ65 Bar Material SUS303

Satellite Part

- φ130×130L SUS303

| Diameter | φ100×110L |

| Material | SUS303 |

Point The crossover stroke enables previously unreachable L-side end face machining with the upper turret on the L side. This enhances the effective use of the three turrets.

Click to play video

| Diameter | φ50 |

| Material | Bar Material SUS303 |

Point For thin materials, simultaneous upper-lower milling with the upper and lower turrets and chamfering with a ball end mill were performed for all machining shapes.

Click to play video

| Diameter | φ50 |

| Material | Bar Material |

Point Focusing primarily on milling, all machining of irregular workpieces was completed from bar material. With minimal turning operations, cycle time reduction and time balance adjustments were achieved through simultaneous upper-lower milling.

Click to play video

| Diameter | φ200×255 |

| Material | Aluminium A7075 |

Point With a Y-axis stroke of ±125mm, X-Y milling of the outer diameter is possible even for large-diameter workpieces with a φ200mm size. Additionally, the tool spindle inclination by 45 degrees enhances turning rigidity and allows for various machining methods, such as groove cutting close to the chuck.

Click to play video

| Diameter | φ65 |

| Material | Bar Material SUS303 |

Point By equipping the upper turret with Y-axis and milling capabilities, helical interpolation for thread milling is possible. Various tools can be mounted for machining, accommodating sizes from small to large diameters.

Click to play video

| Diameter | φ130×130L |

| Material | SUS303 |

Point Efficient machining is achieved through angled hole and inclined surface milling with the tool spindle, combined with simultaneous left-right processing using the lower turret.

Click to play video