General

Base (Optical mechanical industry)

- φ50 Bar material SUS303

Rod Cover

- φ65×800L Aluminium A5056

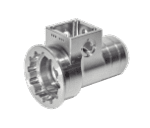

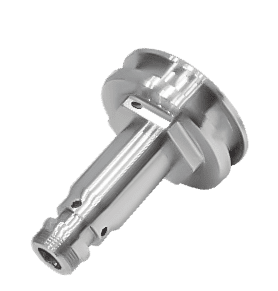

Socket

- φ50 Bar material SUS303

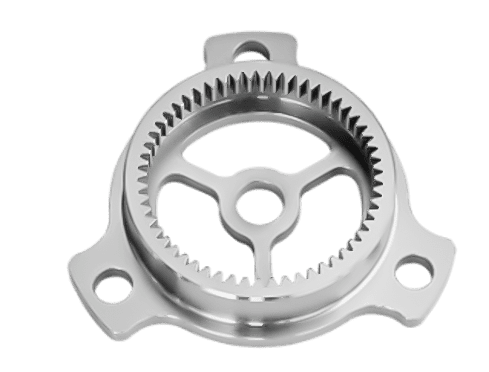

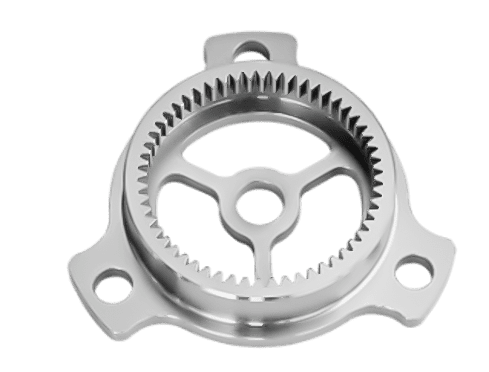

Internal Gear

- φ100×40L SUS303

Joint

- φ40 Bar material SUS303

Sun Gear

- φ46 Bar material SUS303

Planetary Gear

- φ26 Bar material SUS303

Piston

- φ50 Bar material SUS303

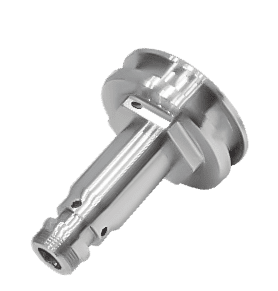

Spindle

- φ180×593L(I.Dφ75mm) S55C

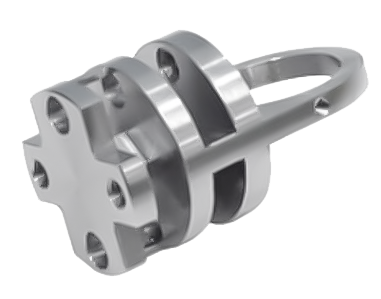

Coupling

- φ70×32L SUS303

Scroll Compressor

- φ140×42L SUS303

Turbine Blade

- φ110×200L SUS304

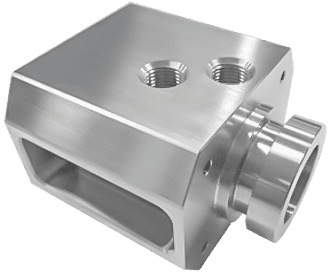

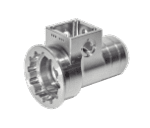

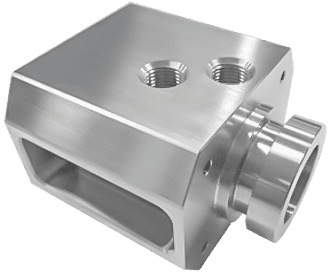

Connector

- φ65 Bar material SUS303

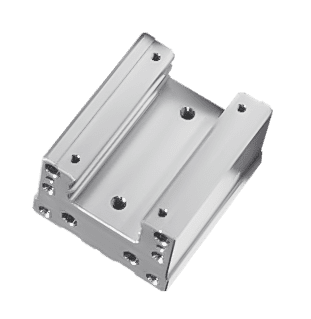

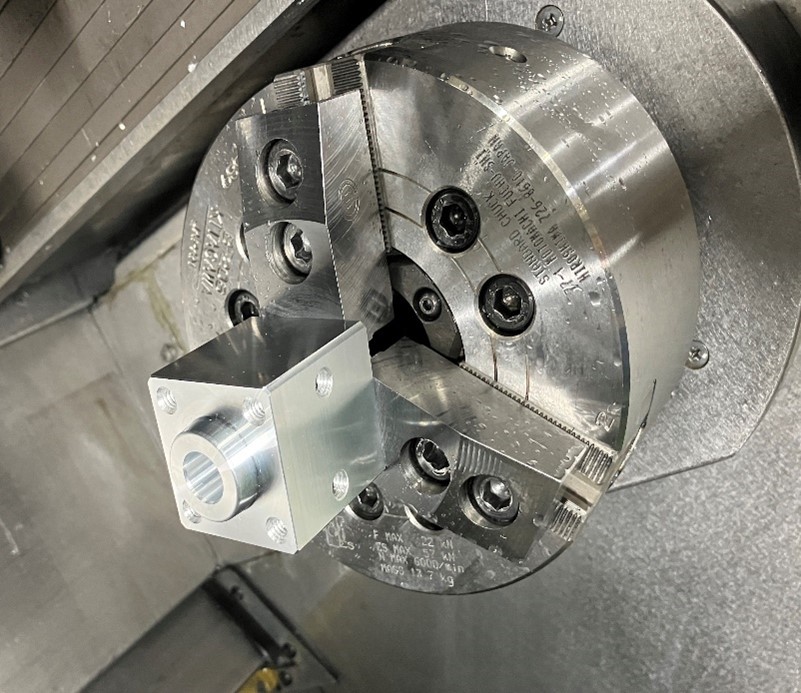

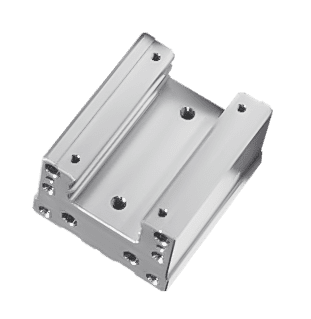

Guide Block

- φ140×100L SCM415

Guide Block

- φ46 Bar material SUS303

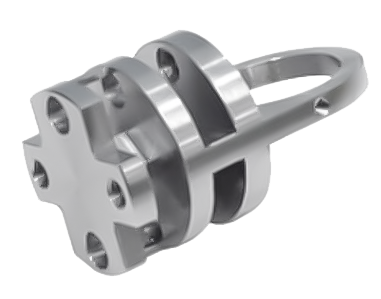

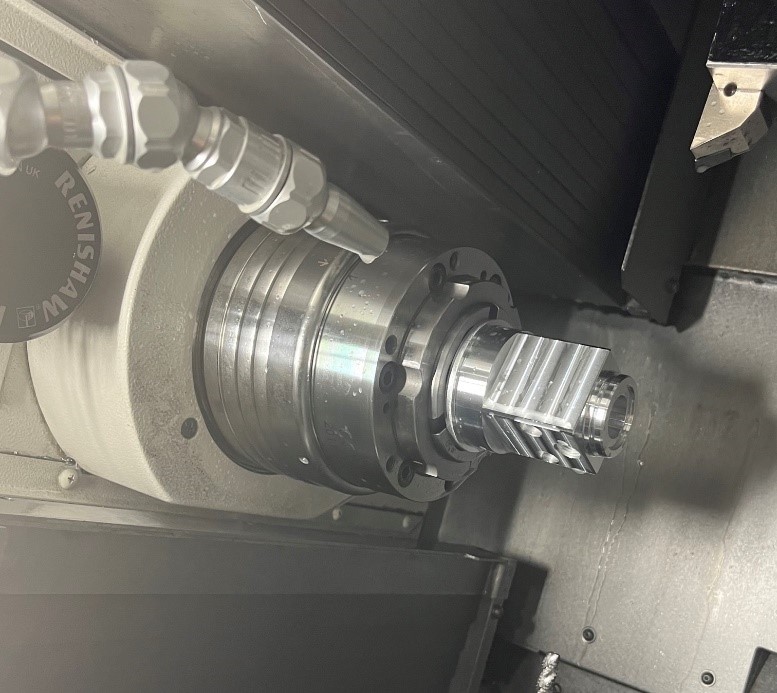

Tool Holder

- φ150×210L S45C/C45/1045

| Diameter | φ50 |

| Material | Bar material SUS303 |

Point Efficient machining has been achieved through simultaneous processing on both the upper and lower sides.

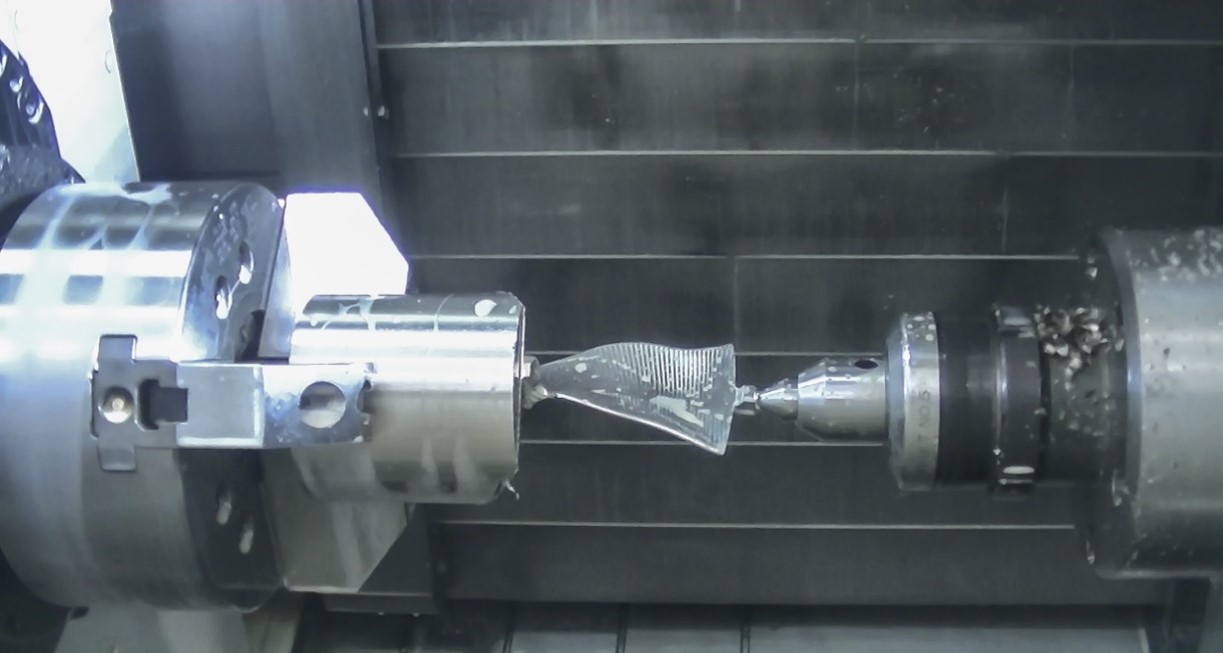

Click to play video

| Diameter | φ65×800L |

| Material | Aluminium A5056 |

Point By utilizing a three-turret machine to streamline numerous processes, simultaneous machining on the L side with the upper and lower turrets and back machining on the R side with the upper turret allow for reduced cycle times and improved time balance.

Click to play video

| Diameter | φ50 |

| Material | Bar material SUS303 |

Point Cycle time has been reduced by combining tool spindles and turrets to machine bar material into finished irregularly shaped workpieces.

Click to play video

| Diameter | φ100×40L |

| Material | SUS303 |

Point Gear skiving machining allows for the processing of both internal and external gears without the need for specialized machines. This enables the consolidation of all processes into a single multitasking machine.

Click to play video

| Diameter | φ40 |

| Material | Bar material SUS303 |

Point High efficiency milling with the lower turret Y-axis and thin part machining with Y-axis milling on both the upper and lower turrets have been achieved.

Click to play video

| Diameter | φ46 |

| Material | Bar material SUS303 |

Point By consolidating gear cutting and phase alignment of the square shapes and gear cutting sections, complete process integration of hobbing and turning operations has been achieved.

| Diameter | φ50 |

| Material | Bar material SUS303 |

Point Cycle time has been reduced through overlapping operations, and high-speed, high-precision polygon machining using the R-side spindle for polygonal shapes has been achieved.

Click to play video

| Diameter | φ150×210L |

| Material | S45C/C45/1045 |

Point For outer diameter machining, a center support is clamped to the R-side chuck, and both the L-side and R-side chucks are employed for dual-support machining. Additionally, an NC steady rest is utilized for face machining, which improves machining accuracy. Furthermore, for inner diameter machining, a steady rest and a 450mm long tool are employed on both the R and L sides, allowing for safe machining of long workpieces similar to spindles.

Click to play video

| Diameter | φ70×32L |

| Material | SUS303 |

Point High-value workpieces have been machined using advanced milling performance, consolidating both machining center and lathe functionalities into a single machine.

Click to play video

| Diameter | φ140×42L |

| Material | SUS303 |

Point High-value workpieces have been machined using advanced milling performance, consolidating both machining center and lathe functionalities into a single machine.

Click to play video

| Diameter | φ110×200L |

| Material | SUS304 |

Point The high-rigidity ATC-type multitasking machine "JX-250" has been adopted, ideal for large-diameter workpieces. It features a tool spindle with a swivel B-axis, enabling milling of free-form surfaces and inclined planes.

| Diameter | φ65 |

| Material | Bar material SUS303 |

Point Simultaneous milling using the Y-axis of the upper and lower turrets enabled high-efficiency machining of block shapes from bar material.

Click to play video

| Diameter | φ140×100L |

| Material | SCM415 |

Point By utilizing a three-turret machine to streamline numerous processes, simultaneous machining on the L side with the upper and lower turrets and back machining on the R side with the upper turret allow for reduced cycle times and improved time balance.

| Diameter | φ46 |

| Material | Bar material SUS303 |

Point Tool change optimization with turret machine and productivity improvement through simultaneous parallel upper-lower and left-right processing have been achieved.

Click to play video

| Diameter | φ150×210L |

| Material | S45C/C45/1045 |

Point The shape of the tool holder is processed with the tool spindle using milling , completely machined from round material. High-speed cutting is achieved while maintaining high precision and rigidity.

Click to play video