Construction

Piston Pump

- φ140×105L SCM420

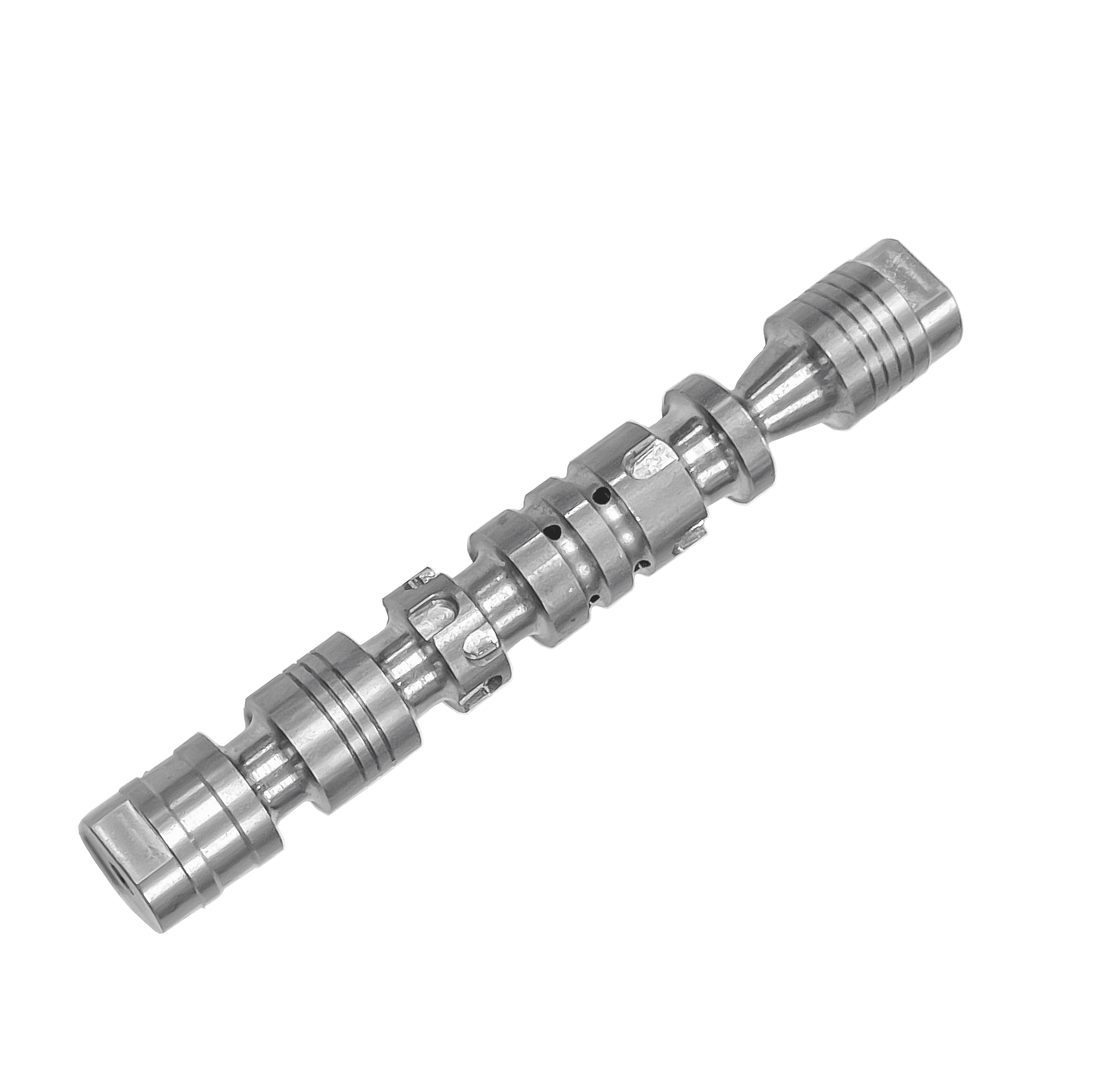

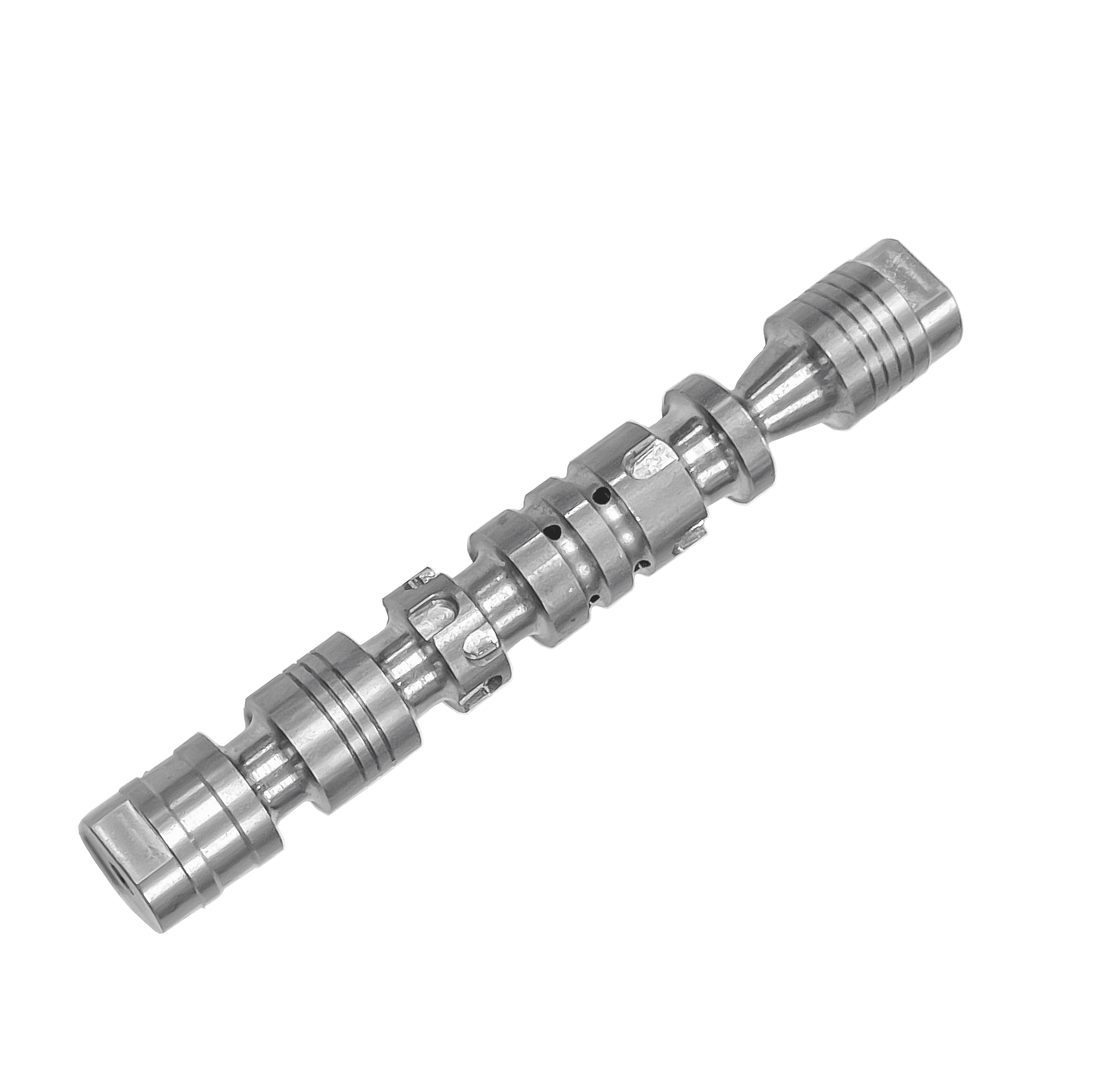

Spool Valve

- φ25 Bar material

Valve

- Φ50×96L SUS303

Connector

- φ25 SUS303

Spline Shaft

- φ52×100L SUS303

Rod End

- φ125×500L S45C

| Diameter | φ140×105L |

| Material | SCM420 |

Point High-precision hole positioning and high cylindricity and roundness achieved with a reamer have been realized, allowing for the production of finished products with a single machine.

| Diameter | φ25 |

| Material | Bar material |

Point It supports various machining methods, including angled hole processing with the swivel B-axis, workpiece deflection prevention with dual clamping, and high-speed, non-step drilling with long drills.

Click to play video

| Diameter | Φ50×96L |

| Material | SUS303 |

Point High-speed milling and drilling at up to 10,000 rpm make it ideal for small-diameter hole drilling and chamfering operations. Simultaneous upper-lower processing significantly reduces machining time and allows for adjustment of time balance between left and right operations.

Click to play video

| Diameter | φ25 |

| Material | SUS303 |

Point Irregular shape was completely achieved from bar material. A 1.5mm gun drill and an effective diagonal milling and chamfering with the B-axis turret are achieved. The finished part can be machined in a single machine.

| Diameter | φ52×100L |

| Material | SUS303 |

Point By combining the previously divided hob machining of the Module 1.5 with a multitasking machine, setup times have been reduced, enabling stable production.

| Diameter | φ125×500L |

| Material | S45C |

Point Using the lower turret for center support enables smooth machining of long workpieces without any issues., for the rod part, an efficient machining of spherical inner ring is achieved by tool spindle.